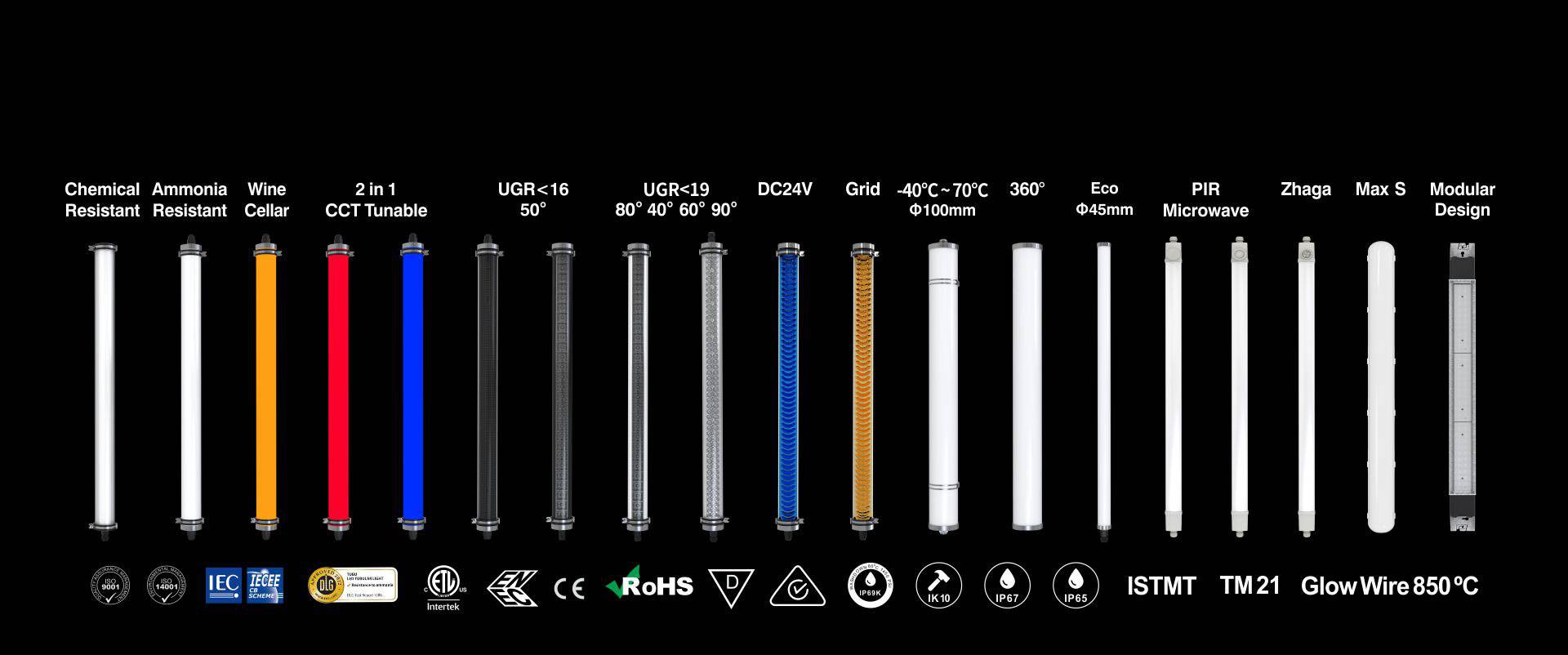

As a professional TUBU supplier, we know the core role of LED tri-proof lamps in harsh industrial environments. Its material selection directly determines the protection performance, service life and lighting effect of the lamps. We specialize in providing high-performance and durable LED tri-proof lamps (waterproof, dustproof, corrosion-resistant) to our global customers. The following is a professional analysis of the application characteristics of PC, PMMA, GRP, stainless steel, tempered glass and its competitiveness in LED three-proof lamps.

Material Characteristics and Application Scenarios

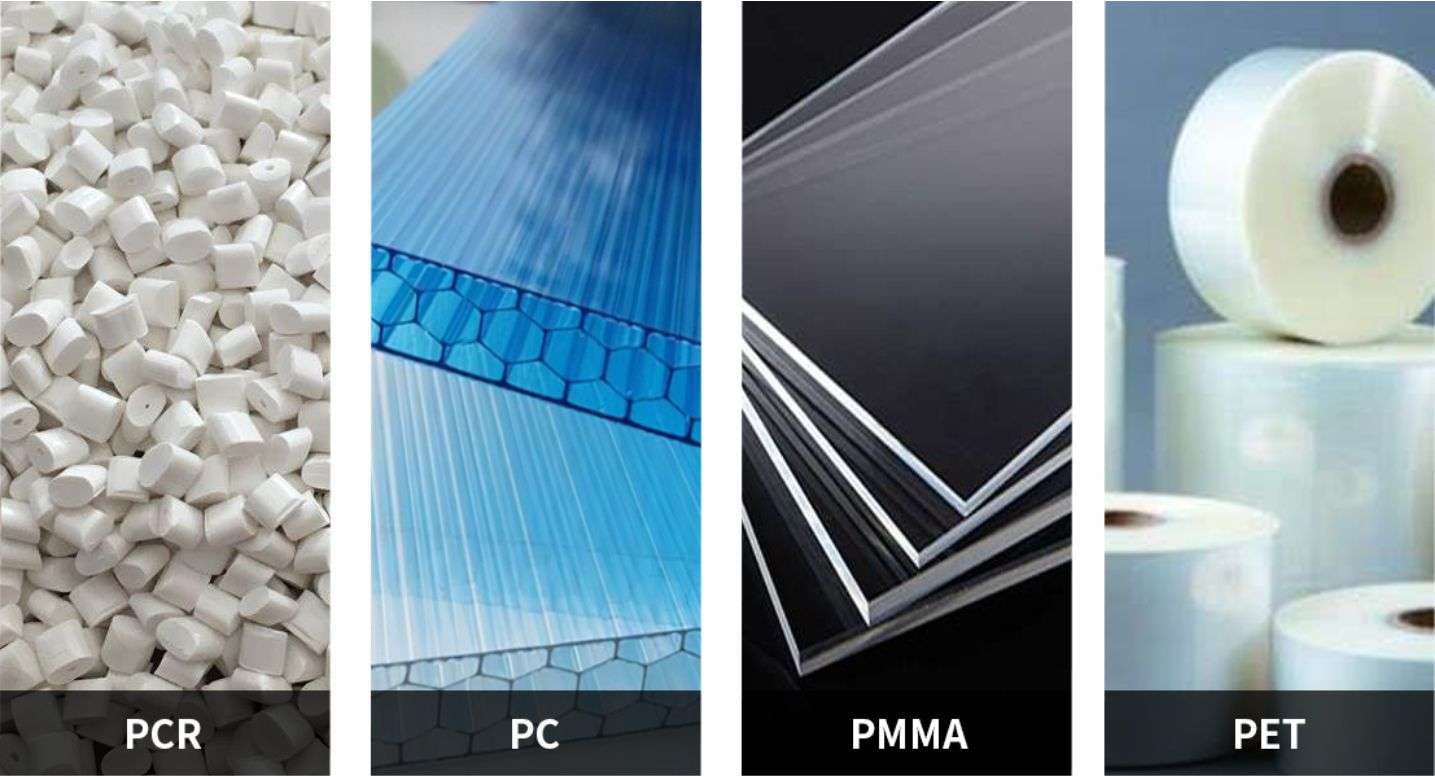

(1) PC (Polycarbonate) LED Tri-Proof Lights

PC Advantage

Extremely strong impact resistance (200 times that of glass, 30 times that of acrylic), PC (polycarbonate) LED tri-proof lights are suitable for environments susceptible to external impact (such as warehouses, workshops).

Wide range of temperature resistance (-40℃~120℃), adapt to high temperature and high humidity environment.

Light transmittance about 85%~90%, can be designed with frosted surface to reduce glare.

PC Disadvantage

Prolonged exposure to UV light may slight yellowing (need to add anti-UV coating).

Chemical resistance is weaker than PMMA and GRP.

TUBU APPLICATIONS

PC (polycarbonate) LED tri-proof lights are recommended for medium corrosive environments and high anti-impact requirements of the scene, such as logistics warehousing, underground parking lots.

(2) PMMA (Acrylic / Plexiglass) LED Tri-Proof Lights

PMMA Advantage

The highest transmittance (92%~95%), light uniformity and softness, PMMA (acrylic / plexiglass) LED three-proof lamps are suitable for precision operational lighting (such as laboratories, food processing).

Excellent weather resistance (UV resistant, not easy to yellow), long outdoor service life.

Lightweight, easy to install.

PMMA Disadvantage

Higher brittleness, PMMA (acrylic / plexiglass) LED tri-proof lights are easy to crack by sharp objects impact.

Temperature resistance is general (-40℃~80℃).

TUBU APPLICATIONS

PMMA (Acrylic / Plexiglass) LED tri-proof lamps are suitable for outdoor advertising lighting, cleanroom and other scenes that require high optical performance.

(3) GRP (Glass Fiber Reinforced Plastic) LED Tri-Proof Lights

GRP Advantage

High strength, corrosion resistance, resistant to strong acid and alkali environment (chemical industry, electroplating workshop).

Good insulation, GRP (Glass Fiber Reinforced Plastic) LED tri-proof light is suitable for high-risk explosion-proof areas.

Lighter weight than metal, strong aging resistance.

GRP Disadvantage

Low light transmittance (need to match with high power light source).

The surface is easy to accumulate dust, GRP (Glass Fiber Reinforced Plastic) LED tri-proof lights need to be cleaned regularly.

TUBU APPLICATIONS

GRP (glass fiber reinforced plastic) LED tri-proof lamp specializes in petrochemical, marine platforms and other extreme corrosive environments, providing customized explosion-proof solutions.

(4) Stainless Steel (304/316L) LED Tri-Proof Lights

Stainless Steel Advantage

Highest mechanical strength, excellent resistance to pressure and deformation.

Resistant to salt spray corrosion (316L stainless steel is suitable for coastal and ships).

High fire rating (A1 grade), stainless steel (304/316L) LED tri-proof light is suitable for high temperature workshops.

Stainless Steel Disadvantage

Stainless steel (304/316L) LED three-proof light is heavy, installation requires reinforced structure.

Higher cost, complicated processing (laser cutting/welding required).

TUBU APPLICATIONS

For metallurgy, mining, ships and other super harsh environments, providing lifelong durable heavy duty lighting solutions.

(5) Tempered Glass LED Tri-Proof Lights

Tempered Glass Advantage

Highest light transmittance (over 97%), no loss of light, tempered glass LED tri-proof light is suitable for high-end commercial space.

High surface hardness (Mohs hardness level 6~7), scratch resistant.

High temperature resistance (can withstand temperature difference of more than 300℃).

Tempered Glass Disadvantage

Subject to extreme impact will shatter as a whole (need to match with protective frame).

High weight, high transportation costs.

TUBU APPLICATIONS

Tempered glass LED tri-proof lights are mainly promoted in shopping malls, gymnasiums and other scenes that require high aesthetics and light efficiency, with explosion-proof film to enhance safety.

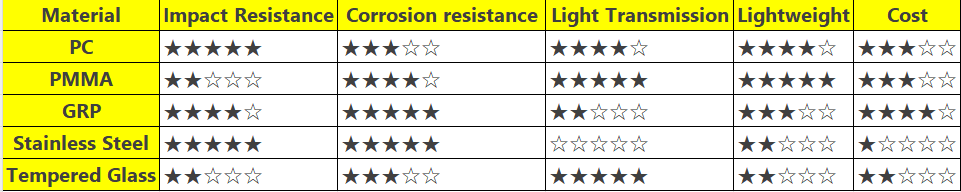

Comprehensive Competitive Comparison (5-Dimensional Score)

LED Tri-Proof Light Material. Who Is Stronger?

Extreme industrial environment (chemical industry, mining): Stainless Steel > GRP > PC

→ Stainless steel and GRP sacrifice light transmission for absolute corrosion resistance and structural strength.

Outdoor high light transmission needs (roads, stadiums): Tempered Glass ≥ PMMA

→ Tempered glass needs to be matched with a protective frame, PMMA is more suitable for low-cost lightweight solutions.

Balanced price/performance ratio (warehouse, parking lot): PC > PMMA

→ PC wins with impact and temperature resistance, PMMA is suitable for low-risk and high light efficiency scenarios.

For further customized solutions, please contact TUBU professional team, we will provide you with free selection guidance and sample testing!